July 6, 2017 — Lyndhurst, NJ — Hop Industries, manufacturer of the durable Hop-Syn synthetic paper, today released helpful tips for finishing and fabricating on the various grades of Hop-Syn synthetic paper. The piece highlights numerous post-press options — from die-cutting, folding and scoring to drilling, sewing and grommeting — along with advice to help customers get the best results with the durable substrate. Contact a Hop-Syn synthetic paper expert at 800-524-0757 or contact us to request the free technical document.

“The finishing and fabricating tips document is a handy reference for packaging firms and print partners using Hop-Syn synthetic paper. For each finishing and fabricating technique, there’s ways to produce it with precision, and this document explains how,” comments Jack Smith, Senior Vice President, Hop Industries.

The Hop-Syn technical tips for finishing and fabricating is a valuable resource to get the most out of the synthetic paper grades while extending the life of the processing equipment. For example, it explains why to use a wax paper or carbon paper when drilling in short lifts and highlights the machine direction to get the best folding. It also gives the ratio of web speed to die pressure, and explains why maintaining accurate adjustment of die-to-anvil contact is important for success.

Hop-Syn synthetic paper is a single-layered mineral filled polypropylene that comes in six grades: XT, BL, TO, G1, G2, and DL. Each synthetic paper grade is developed for specific applications such as P-O-P displays, banners, blockout and backlit signs, as well as hang tags, book covers, maps and more.

For more information, visit www.hopsyn.com or call Hop Industries at 800-524-0757.

Choosing the right substrate can either make or break an advertising campaign, and the experts at Hop Industries can help you get it right. Want to know where and when synthetic paper should and shouldn’t be used? Team members Jack Smith, William Latham and John Callandrillo each have their areas of expertise when it comes to synthetic paper. Here’s a breakdown:

Choosing the right substrate can either make or break an advertising campaign, and the experts at Hop Industries can help you get it right. Want to know where and when synthetic paper should and shouldn’t be used? Team members Jack Smith, William Latham and John Callandrillo each have their areas of expertise when it comes to synthetic paper. Here’s a breakdown:

The uses of the

The uses of the

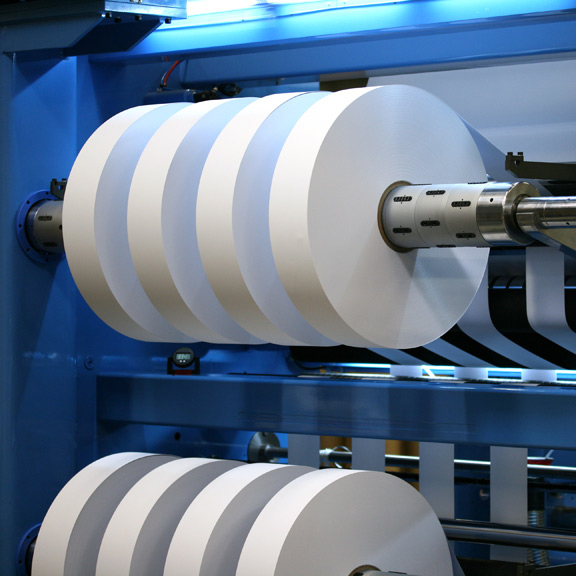

Print partners are taking full advantage of Hop Industries’ quick turnaround of Hop-Syn synthetic paper orders. With a wide variety of inventory totaling more than one million pounds of the popular substrate on hand in Hop’s NJ warehouse, orders are shipped within 24 orders of being placed. For custom-sheets and roll sizes that need to be converted, Hop can produce these orders within a minimum of 2-3 days. Now that’s fast!.

Print partners are taking full advantage of Hop Industries’ quick turnaround of Hop-Syn synthetic paper orders. With a wide variety of inventory totaling more than one million pounds of the popular substrate on hand in Hop’s NJ warehouse, orders are shipped within 24 orders of being placed. For custom-sheets and roll sizes that need to be converted, Hop can produce these orders within a minimum of 2-3 days. Now that’s fast!. Brand manufacturers and their print partners are welcome to visit the Hop-Syn warehouse to see Hop’s in-house converting and stock inventory. Print partners are also encouraged to reserve the Hop-Syn synthetic paper and have it stored in Hop’s warehouse for up to six months for guaranteed inventory of special sizes.

Brand manufacturers and their print partners are welcome to visit the Hop-Syn warehouse to see Hop’s in-house converting and stock inventory. Print partners are also encouraged to reserve the Hop-Syn synthetic paper and have it stored in Hop’s warehouse for up to six months for guaranteed inventory of special sizes.

Hop Industries’ booth at

Hop Industries’ booth at