October 5, 2017 — Lyndhurst, NJ — Hop Industries, manufacturer of the durable Hop-Syn synthetic paper, today announces that Electronics For Imaging, Inc. (Nasdaq:EFII) will demonstrate how easy it is to produce high quality, backlit signage using the EFI™ VUTEk® LX3 Pro printer and Hop-Syn BL synthetic paper at its booth #1501 at 2017 SGIA Expo. At the Expo, which takes place in New Orleans, Oct 10-12, attendees are invited to visit the EFI booth to experience live demonstrations of the 3.2-meter LED inkjet printer creating backlit signage using the durable and environmentally friendly Hop-Syn BL 10mil. Free samples of the backlit signage will also be available at Hop’s booth #4017.

“The live demonstrations at SGIA Expo provide a wonderful opportunity to showcase high-value, backlit applications achievable with EFI inkjet technology and Hop-Syn,” comments Ken Hanulc, VP of marketing, EFI inkjet. “Attendees can take the samples and show their customers the new and innovate ways to use backlit signage in their advertising strategies.”

“We are delighted to collaborate with EFI again”

“We are delighted to collaborate with EFI again,” comments Jack Smith, Senior Vice President, Hop Industries. “SGIA Expo attendees can see the print quality of the VUTEk and Hop-Syn backlit signage first hand.”

Hop-Syn BL is an environmentally friendly synthetic paper that is used for back lit P-O-P signs, transit and airport displays, bus shelters, fine art, and more. It can be printed by flexography, offset, screen, thermal transfer and inkjet. The VUTEk LX3 Pro is designed for high production throughput. It helps customers print high volumes with shorter lead times, while maintaining image quality.

Free passes to SGIA Expo are available upon request from Hop Industries. For more information, contact Hop Industries at 1-800-524-0757 or visit www.hopsyn.com.

About Hop-Syn

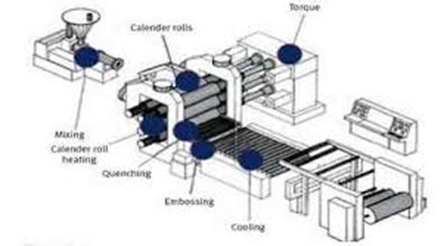

Hop-Syn® is a division of Hop Industries Corp. based in Lyndhurst, NJ. Hop-Syn is a synthetic paper constructed from polypropylene (PP) resins and calcium carbonate (CaCO3), which provide extra durability and weather resistance over traditional pulp-based papers. Customers use Hop-Syn to print high quality graphics via offset litho, uv offset, flexo, screen, uv ink jet or thermal transfer equipment. Each Hop-Syn grade has unique characteristics to match the application, hence the phrase, “The Application Specific Synthetic Papers.” If customers need foldability for a map, there’s a grade for that. If customers need thickness for a P-O-P sign, there’s a grade for that. If customers need translucency for a light box, there’s a grade for that. If customers need extra opacity for a block out window sign, there’s a grade for that. For more information, visit www.hopsyn.com or call 800-524-0757.