The Hop-Syn booth at GlobalShop is a must-visit for GlobalShop attendees! Here, Jack Smith gives a quick report from the Expo. If you’re in Vegas, visit us at booth #2060.

The Hop-Syn booth at GlobalShop is a must-visit for GlobalShop attendees! Here, Jack Smith gives a quick report from the Expo. If you’re in Vegas, visit us at booth #2060.

March 23, 2017

March 23, 2017

When did you join Hop Industries? What were some of the attributes that you appreciated about the company/products?

I first joined Hop Industries in May 2004 right after graduating from Montclair State University. I interviewed at many companies selling commodity, or “me-too” type of products that really did not spark much personal interest. When I interviewed at Hop and learned about their products and how they focused on a very specialized market segment of the printing industry, I jumped at the opportunity to join the sales team of such an up and coming brand in the market. I was shown several samples on how Hop-Syn was being used for applications such as menus, signage, tags, and packaging. Selling to these types of industries sparked a lot of interest and challenges to an emerging market segment of the printing industry.

How have the synthetic paper market and related technologies changed in the last decade?

When I first started with Hop Industries, finding printers that printed on plastics or synthetic papers were few and far between. If I had to put a ratio to it, I would say that 1 out of every 25 printers that I would call on would have an interest in printing on synthetic papers. Many printers would not even consider printing on synthetic paper or plastic due the many changes on press and special inks that were required. As newer technology such as better ink formulations and fountain solutions emerged, and the rising popularity of UV technology, that ratio quickly turned to 1 out every 10 printers who would be interested in using our product by 2012. Today with the wide and grand format market on the rise, particularly with the UV Inkjet, 1 out of every 5 print shops would have interest in Hop-Syn. This ratio will continue to get smaller as newer technology emerges that adapts to printing on plastic substrates.

How are these changes impacting big brands?

With newer technologies, big brands have more options now than ever before to print on media such as Hop-Syn. Big brands can now print big runs and small runs on plastic media at more affordable prices due to the new technologies.

What advice do you have for companies that haven’t used Hop-Syn synthetic paper in their print promotions? Do print buyers need to specify Hop-Syn?

For companies that have not used Hop-Syn, I would recommend that they contact Hop and discuss their durable printing applications with one of our experienced sales professionals. Hop-Syn is known in the industry as the “application specific” synthetic paper, designed to meet specific requirements for high performance printing demands. Print buyers in particular do need to specify Hop-Syn. But before they can do that, we need to educate them on the quality our material has for their applications and the advantages over competing products in the market.

March 20, 2017

March 20, 2017

We like the Hop-Syn synthetic paper because there’s no limit to what we can do. It’s the easiest folding synthetic paper in the market.”

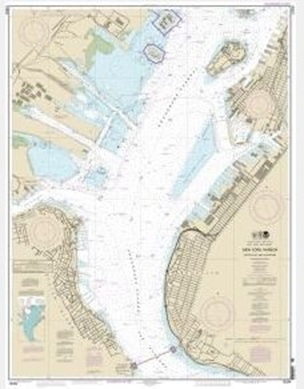

As one of the nation’s oldest map printers, Williams & Heintz Map Corporation knows how to keep customers coming back. In business since 1921, the family-run map printing company continually strives to produce high-quality custom maps with the least amount of impact on the environment. Thanks to Hop-Syn synthetic papers, they can accomplish both.

“We print maps for our customers — entrepreneurs, government agencies and map publishers — on Hop-Syn synthetic papers because they choose it,” comments Mark Budd, Treasurer, Williams & Heintz Map Corporation. “It’s a combination of the quality and price that makes it an easy decision.”

Environmentally Friendly Map Printing Specialists

Unlike traditional printing, map printing is a specialization. Budd comments, “There’s a special craft to producing, printing, and folding maps. It’s different than any other type of sheetfed work, and we regularly push the boundaries for our customers. We like the Hop-Syn synthetic paper because there’s no limit to what we can do. It’s the easiest folding synthetic paper in the market.” The staff also appreciate that Hop-Syn is listed under recycling code number 5, and can be recycled with polypropylene plastics. “Many customers include the recycling logo on the maps,” he adds.

Hop-Syn G1 paper is a synthetic paper manufactured by Hop Industries. The G1 grade is popular with map printers because it folds as easy as paper. Hop-Syn G1 is made with over 25% calcium carbonate filler, which gives it the market’s best foldability. The Hop-Syn substrate is also one of the fastest drying and scuff-resistant synthetic papers used by printers in the map industry.

Environmentally Speaking

The Hop-Syn G1 synthetic paper grade is 100% recyclable. Based on Hop-Syn G1 being made into a single layer substrate, from a mixture of polypropylene and calcium carbonate, it allows Hop-Syn to have the printing properties of paper, but with the durability, weather resistance, and waterproof properties of plastic. The environmental advantages of the Hop-Syn paper are especially important to Williams & Heintz, and are in line with the company’s sustainability initiatives. Its printing operation also uses no toxic solvent inks or dangerous UV processes. The company recycles its synthetic paper waste with a third party, which turns the excess scrap into functional items like park benches and potting containers.

The Hop-Syn G1 synthetic paper grade is 100% recyclable. Based on Hop-Syn G1 being made into a single layer substrate, from a mixture of polypropylene and calcium carbonate, it allows Hop-Syn to have the printing properties of paper, but with the durability, weather resistance, and waterproof properties of plastic. The environmental advantages of the Hop-Syn paper are especially important to Williams & Heintz, and are in line with the company’s sustainability initiatives. Its printing operation also uses no toxic solvent inks or dangerous UV processes. The company recycles its synthetic paper waste with a third party, which turns the excess scrap into functional items like park benches and potting containers.

It’s in the Fold

Williams & Heintz prints a variety of maps, such as hiking trails and boating guides, ranging from the simplest 1-color map to complicated 12-color maps, from 3×5-inches to 47¼ x 63-inches. Because of their experience and capabilities, Williams & Heintz recently became authorized by the National Oceanic and Atmospheric Administration (NOAA) to print paper nautical charts on demand.

“We like working with the Hop Industries sales team. Customer service is always excellent and very responsive. Hop-Syn’s in-house custom sheeting also makes it easy for us to provide our customers with maps that meet their specific dimensions, in a timely manner,” comments Budd.

For more information about Williams & Heintz Map Company, visit www.whchartbook.com. For more information about Hop-Syn synthetic papers, visit www.hopsyn.com or call 1-800-524-0757.

March 10, 2017

March 10, 2017

Hop Industries, makers of Hop-Syn synthetic paper, in conjunction with Augusta, Maine-based J.S. McCarthy Printers are proud to be involved with Wreaths Across America’s annual tribute to U.S. veterans. Each year, Wreaths Across America works with J.S. McCarthy to produce the tags on Hop-Syn synthetic paper, which is chosen for its ability to meet extreme weather conditions.

Wreaths Across America, which started out as one man’s annual tribute, now represents a legion of volunteers that participate in the wreath-laying ceremony to honor our nation’s heroes in over 1,230 cemeteries nationwide.

Tags That Endure

J.S. McCarthy chooses the Hop-Syn XT paper grade for the Wreaths Across America tags because it stands up to the elements. Hop-Syn XT is an extra tear-resistant synthetic paper made from a unique mixture of calcium carbonate and polypropylene resin. It delivers the printing performance of a fine offset paper thanks to its high dyne level and smooth matte finish. The substrate is also 100% recyclable, and is ideal for outdoor applications like the annual Wreaths Across America initiative.

Remember. Honor. Teach.

Wreaths Across America provides several programs to honor U.S. veterans, including the popular “Thanks a Million” campaign which distributes cards to people all over the country to give veterans as simple “thank you” for their service. The organization also participates in veterans’ events throughout the year and is committed to teaching younger generations about the value of their freedoms and the importance of honoring those who sacrificed to protect those freedoms.

To learn more or to get involved with Wreaths Across America, visit www.WreathsAcrossAmerica.com.

March 7, 2017

March 7, 2017

Yes, Hop-Syn is making waves! The synthetic paper leader is featured in another top industry trade magazine, PrintingNews, “Synthetic Papers make Waves in Wide Format, Packaging, and Elsewhere.” Industry veteran and author Richard Romano addresses how the Hop-Syn synthetic paper is fast becoming a mainstream substrate for wide format printing and packaging applications.

In the article, Romano writes, “The Hop-Syn synthetic papers are also popular for waterproof maps and menus, horticultural tags and plant stakes, and warranty tags for outdoor products, as well as POP displays, and are also turning up in more and more packaging applications.”

The Durable Substrate

Addressing the durability of synthetic paper, Romano writes, “The apt term “durables” is also used to describe these materials, since they’re hard to rip or tear. They are also waterproof and greaseproof, which is not only useful for outdoor applications, but also indoor ones such as restaurant menus, which are often subject to being spilled on and otherwise besmeared.”

Commenting in the article is Jack Smith, senior vice president for Hop Industries, manufacturer of Hop-Syn synthetic papers. Here, he explains the chemical makeup of the synthetic paper. “Synthetic paper is a white opaque plastic that is made from either polypropylene and polyethylene plastic that has been modified with a calcium carbonate coating or clay filler to enhance its dyne level for better ink adhesion and brightness for printing durable signs and posters by flexo, offset, inkjet, and laser printing.”

Is Synthetic Paper Environmentally Friendly?

Romano writes, “Being plastic, synthetic papers often get a bad rap for being environmentally unfriendly, but that isn’t necessarily the case.” Smith comments, “Most synthetic papers are made from polypropylene and/or polyethylene resin, which are environmentally friendly and contain no heavy metals, chlorine, phthalates, or other carcinogens that are damaging to the environment.” Click here to read the full article. For more information about Hop-Syn synthetic paper or for free samples, visit www.hopsyn.com or call 800.524.0757.

February 16, 2017

February 16, 2017

Another great article about Hop-Syn synthetic paper — the alternative to banner vinyl. Read the article, ‘Options a Plenty’ in the February 2017 issue of Digital Output.

The following is an excerpt from the article:

Hop Industries’ most popular banner vinyl alternative is Hop-Syn XT. The synthetic paper is easily die cut and can also be grommeted and printed on both sides. It’s a single-layered mineral-filled polypropylene, which is produced using a calender manufacturing process. This finishing process creates a smooth white matte surface. The XT grade is UV resistant up to one year outdoor, and resistant to scuffs, weather, and tearing.

February 14, 2017

February 14, 2017

February 14, 2017 — Lyndhurst, NJ — Hop Industries, supplier of the Hop-Syn synthetic paper, is pleased to announce a print campaign with swissQprint, manufacturer of large format UV printers. The print campaign is designed to demonstrate the flexibility of the various grades of Hop-Syn synthetic papers with the swissQprint wide format UV printers. The Hop-Syn grades used for this campaign are Hop-Syn BL, TO and XT. Each grade is 100% tree-free, and is ideal for a variety of applications such as backlit displays, waterproof block-out promotions, and whenever a sharp image needs to create an impact. When using the pin registration of the swissQprint equipment, customers gain a competitive advantage because of the breadth of applications that it allows. Both companies will be mailing the print samples to customers in early February upon request.

“We are excited to work with swissQprint for this print campaign,” comments Jack Smith, Senior Vice President, Hop Industries. “Its UV printers are efficient and well-designed, and can easily handle the variety of formats that our Hop-Syn paper comes in, small- or large-format, sheets or rolls, standard or custom-sized. It’s a good fit for both our customer bases to see how the best print solutions work together.”

“The variety of sizes that the Hop-Syn substrate comes in is ideal for our swissQprint equipment,” comments Carmen Eicher, Vice President of Marketing, swissQprint. “swissQprint is pleased with the print quality results of the Hop-Syn synthetic paper, and with this print campaign, we can share the value with more of the print community.”

For more information or to receive print samples of the Hop-Syn and swissQprint campaign, visit www.hop-syn.com or call Hop Industries at 800-524-0757.

About swissQprint

swissQprint is an independent joint-stock company based in Kriessern, Switzerland. The company develops and manufactures the high-end digital printing systems in Switzerland. The US subsidiary swissQprint America sells the swissQprint equipment directly in the United States. swissQprint is used by professionals to apply lettering and artwork onto a wide variety of surfaces. The company’s long-standing experience and specialization make it a driver of innovation in digital printing technology. Graphics businesses and industrial companies turn to swissQprint for well-engineered, practical solutions that promote real competitive advantage. Three swissQprint models cover various productivity levels: The Oryx 2 ranks as a professional starter model, with a maximum production rate of 700 ft²/h. The Impala 2 delivers output rates of up to 1938 ft² per hour. The Nyala 2 model produces at a maximum rate of 2217 ft²/h. All models are basically flatbed printers with add-on options, such as a roll-to-roll, a board, and a robotic feature that loads and unloads the printers with media. For more information, visit www.swissqprint.com or call 224-802-2770.

About Hop-Syn

Hop-Syn® is a division of Hop Industries Corp. based in Lyndhurst, NJ. Hop-Syn is a synthetic paper constructed from polypropylene (PP) resins and calcium carbonate (Cao3), which provides extra durability and weather resistance over traditional pulp-based papers. Customers use Hop-Syn to print high quality graphics via offset litho, uv offset, flexo, screen, uv ink jet or thermal transfer equipment. Each Hop-Syn grade has unique characteristics to match the application, hence the phrase, “The Application Specific Synthetic Papers.” If customers need foldability for a map, there’s a grade for that. If customers need thickness for a POP sign, there’s a grade for that. If customers need translucency for a light box, there’s a grade for that. If customers need extra opacity for a block out window sign, there’s a grade for that. For more information, visit www.hopsyn.com or call 800-524-0757.

February 10, 2017

February 10, 2017

Tree-free Hop-Syn synthetic paper is emerging as the alternative to many traditional substrates, especially PVC plastic. More than just its environmental advantages, the Hop-Syn synthetic paper prints better than plastic and provides greater tear resistance. Jack Smith of Hop Industries, the manufacturer of Hop-Syn synthetic paper, shares some insight about how its substrate compares to other plastics.

Why should printers and brands choose Hop-Syn versus PVC-based vinyl for their printed promotions?

Jack Smith:: Printers and brands are choosing Hop-Syn synthetic paper because it’s more durable, tear resistant, waterproof, and weather resistant as compared to other plastics such as PVC vinyl and polystyrene. Hop-Syn’s higher dyne level is for better ink adhesion. Plus, its bright white finish allows printers to produce sharper graphics with a higher color resolution, which enhances the printed image. The Hop-Syn substrate also meets brands’ sustainability requirements because it is more environmentally friendly and 100% recyclable, whereas PVC plastics are not.

What makes Hop-Syn more environmentally friendly than other plastics?

JS:: Hop-Syn synthetic paper contains no heavy metals, chlorine, phthalates or other carcinogens found in other plastics, which are damaging to the environment. The Hop-Syn substrate is made from polypropylene and calcium carbonate, and is 100% recyclable under the recycling code #5.

What makes Hop-Syn different than other synthetic papers?

JS:: Hop-Syn synthetic paper is produced by high speed calendar into a single layered substrate made from a unique mixture of polypropylene (PP) resin, CaCO3 (calcium carbonate) and TiO2 (titanium dioxide). The calendaring process allows Hop-Syn to be formulated into different grades that offer a wide range of physical properties and thicknesses from .003 up to .035 gauge, up to a maximum roll width of 72″. This patented formulation contributes to a unique combination of features such its bright white finish, high opacity, high dyne level, tear resistance, UV resistance (up to one year outdoors), and a wide temperature resistance from -60F up to 220F.

What are the advantages of calendering?

JS:: Hop-Syn’s patented calendering process gives it its distinct characteristics. Unlike die extrusion or blown film extrusion used by other synthetic paper companies, the calendering process can produce a more uniform gauge control of +/- 5%. This allows flexo, offset and UV inkjet printers to print Hop-Syn synthetic paper at faster speeds for higher production and a more consistent print image. Choosing the right grade of Hop-Syn can unlock the unique physical properties that enable more complex applications to be easily manufactured.

How is Hop-Syn used by brands?

JS:: Based on its diverse printing properties and wide range of gauge thickness, Hop-Syn is suitable for printing high quality retail posters, store signs, menus, ID cards, horticultural tags, maps and manuals, where the application requires durability and a lasting image that will hold up in harsh environments. The substrate is a tear resistant, white opaque plastic, that is 100% waterproof. With a smooth matte finish and a +/- 5% gauge tolerance Hop-Syn synthetic papers offer the print performance of paper, with the weather resistance and durability of plastic.

How quick can printers receive an order of Hop-Syn?

JS:: We can ship within 24 hours. Our NJ warehouse stores over 1,600,000 pounds of inventory. We also offer in-house slitting and sheeting capabilities for custom sheets and master rolls.

For test samples, technical information, or a price quote, contact Hop Industries at 1-800-524-0757.

February 8, 2017

February 8, 2017

The ‘Attractive Substrate’ featuring Hop-Syn Synthetic Papers, among others, gains recognition from the Jan/Feb 2017 issue of Label & Narrow Web. Read Steve Katz’s article.

The following is an excerpt from the article:

According to Jack Smith, his company’s Hop-Syn synthetic paper has advantages relating to improvements in printing process efficiencies. He explains: “Hop-Syn is manufactured by the calendering process, which can produce a more uniform gauge control of +/- 5%. This allows flexographic and offset printers to print Hop-Syn synthetic paper at faster speeds for higher production and a more consistent print image. “The calendaring process also allows Hop-Syn to be made in a wide range of thicknesses from .003 up to .035 gauge, and maximum roll widths of up to 72″.”

Hop-Syn synthetic papers are offered in a wide variety of paper grades, which are formulated from polypropylene (PP) resin with CaCO3 (calcium carbonate) and Tio2 (titanium dioxide) added to enhance its dyne level, brightness and opacity. “Although each grade of Hop-Syn may look similar in matte finish, the properties of each Hop-Syn grade are custom made to meet the opacity, brightness, tensile strength and elongation properties that the application requires,” Smith says. “This makes Hop-Syn more adaptable to different applications, which is why it is referred to as ‘The Application Synthetic Paper.’ Also, Hop-Syn is produced under ISO 9000 standards, and meet the environmental standards of CONEG and ROHS for North America.”

All Hop-Syn synthetic paper grades are 100% recyclable, waterproof, tear resistant, and temperature resistant from -60°F to 220°F. Hop-Syn papers are ideal for multiple printing processes, including offset, lithography, UV offset, flexo, screen, UV inkjet and thermal transfer printing. “With in-house slitting and sheeting capabilities, combined with over 1,600,000 pounds of inventory, we have the ability to ship custom sheets and master roll inventory within 24 hours from the date of order,” Smith says. “For testing purposes, we offer free samples to evaluate the print quality and durability of any specific Hop-Syn grade for comparison to any other substrate.”

January 3, 2017

January 3, 2017

Today’s print facilities welcome custom-sized print projects when its done on Hop-Syn synthetic papers. This is because of Hop-Syn’s in-house converting facilities, which makes it possible for printers to receive custom-sized substrate within 3 days of an order. Many printers regard the manufacturer’s NJ-based warehouse as an extension of the their own — the turnaround is quick, and the service is top-notch.

Hop-Syn synthetic papers are used by major brands and their print partners for a variety of signage and display applications, from POP displays and banners to backlit transit signs and fine art displays. The synthetic paper is constructed from polypropylene (PP) resins for extra durability over traditional pulp based papers. Hop Industries stocks up to 1,600,000 lbs of the synthetic paper substrate, and can ship standard stock sizes within 24-hours.

For almost four decades, printers rely on Hop for their standard and custom-sized sheets and rolls for a variety of print projects in the offset, flexo and wide format UV inkjet markets. The company has built a strong reputation for providing quick service, custom sizes, and quality products that has made Hop-Syn synthetic paper one of the market’s first choice for durable substrates. Over this period of time, Hop has built the largest, most diversified synthetic paper inventory program in the United States, facilitated by its converting capability and knowledgeable staff.

Hop’s in-house converting facility offers print providers with unprecedented options for all their synthetic paper projects. For example, its roll slitters can custom-slit the synthetic substrate from 1-inch up to 60-inches in width. Hop’s large-format guillotine sheeters are all computer automated and can produce custom sheet sizes from 8-1/2” x 11” up to 61” x 83”.

For fast turnaround, Hop stocks a wide variety of master rolls (38-, 50-, 55-, 61- and 62-inches) as well as a large selection of standard sheet sizes 25” x 38”, 26” x 40” and 28” x 40” that can be shipped within 24-hours.

To place an order or for more information, call 1-800-524-0757 or visit www.hopsyn.com.